About

Sand Casting

Macraft offers sand casting services, they provide solutions for producing metal parts that are often complex and large. Here’s an overview of what Macraft’s sand casting services might include:

Macraft’s Capabilities:

Precision and Consistency: Ensuring that every cast part meets stringent dimensional and material specifications.

Pattern Design and Fabrication: Creating custom patterns tailored to specific part designs and material requirements.

Material Expertise: Advising on the best metals and alloys for specific applications to ensure optimal performance and durability.

Prototyping: Offering sand casting for prototype parts to test designs before full-scale production.

High-Volume Production: Efficiently handling large production runs with consistent quality.

Secondary Process:

Heat Treatment: Enhancing material properties such as strength, hardness, and wear resistance.

Machining: Offering post-casting machining services to achieve tight tolerances and precise features.

Assembly: Providing assembly services for multi-component products.

Packaging: Customized packaging solutions for safe transportation of cast parts.

Logistics: Managing the logistics of delivering parts to customers efficiently.

Industries we serve:

Automotive: Engine blocks, cylinder heads, and other critical components.

Aerospace: Turbine blades, housings, and structural parts.

Industrial Equipment: Pumps, valves, and machinery components.

Construction: Architectural elements, manhole covers, and structural parts.

Marine: Propellers, anchors, and various marine fittings.

Art and Sculpture: Artistic pieces and custom sculptures

By offering comprehensive sand casting services, Macraft can support a wide range of industries, providing durable, high-quality metal components that meet specific application needs.

About

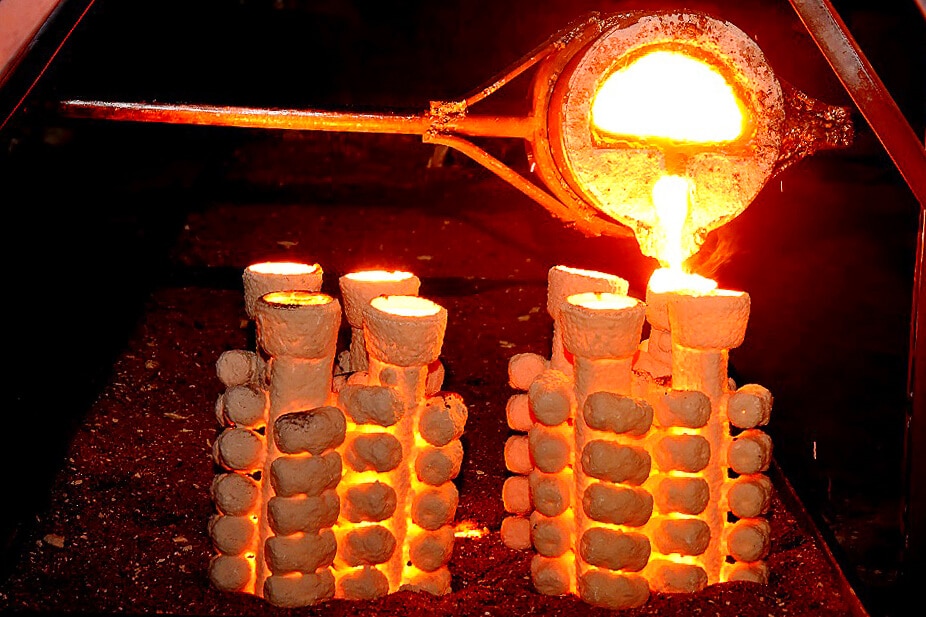

Investment Casting

Macraft offers investment casting services, they provide a solution for producing high-quality components with excellent surface finish and dimensional accuracy. Here’s an overview of what Macraft’s investment casting services might include:

Macraft’s Capabilities:

Quality Assurance: Implementing stringent quality control measures to ensure each cast part meets exacting standards.

Custom Pattern Design: Creating wax patterns tailored to specific part designs, ensuring precise replication in the final metal cast.

Material Expertise: Offering guidance on selecting the best materials for specific applications, ensuring optimal performance and durability.

Prototyping: Providing investment casting services for prototype parts to validate designs before full-scale production.

High-Volume Production: Efficiently handling large production runs while maintaining consistent quality.

Additional Services.

Heat Treatment: Offering heat treatment processes to enhance the mechanical properties of the cast parts, such as increasing strength or hardness.

Machining: Providing post-casting machining services to achieve tight tolerances or add additional features to the cast parts.

Assembly: Capable of assembling cast components into final products or sub-assemblies.

Packaging: Customized packaging solutions to protect the cast parts during transportation.

Logistics: Managing the logistics of delivering cast parts to customers, ensuring timely and safe delivery

Industries we serve:

Art and Jewelry: Detailed sculptures, custom jewelry, and ornamental pieces.

Aerospace: Turbine blades, structural components, and intricate engine parts.

Automotive: Engine components, exhaust system parts, and transmission components.

Medical: Surgical instruments, implants, and dental devices.

Industrial Machinery: Valves, pump components, and wear-resistant parts.

Military and Defense: Precision components for weapons systems and specialized equipment.

By offering comprehensive investment casting services, Macraft can support a wide range of industries in producing high-quality, precision metal components that meet exacting standards and complex requirements.

.

About