About Us

Cnc Machining

Macraft offers CNC machining services, they provide a method for creating intricate and accurate components from a wide range of materials. Here’s an overview of what Macraft’s CNC machining services might include:

Macraft’s Capabilities:

Advanced CNC Machines: Equipped with state-of-the-art CNC machines capable of multi-axis machining, ensuring the ability to produce complex and precise parts.

Custom Part Production: Offering the ability to produce custom parts tailored to specific designs, sizes, and performance requirements.

Prototyping: Providing CNC machining services for prototype parts to validate designs before full-scale production.

High-Volume Production: Efficiently handling large production runs while maintaining consistent quality and short lead times.

Material Expertise: Advising on the best materials for specific applications, ensuring optimal performance and durability.

Secondary Process:

Logistics: Managing the logistics of delivering machined parts to customers, ensuring timely and safe delivery.

Assembly: Assembling machined components into final products or sub-assemblies as required.

Surface Treatment: Providing coatings, anodizing, or other treatments to improve corrosion resistance, wear resistance, or other surface properties.

Packaging: Customized packaging solutions to protect the machined parts during transportation.

Industries we serve:

Consumer Products: High-end custom products, accessories, and prototypes for consumer goods.

Aerospace: Engine components, structural parts, and other precision parts requiring high strength and accuracy.

Automotive: Engine blocks, transmission parts, and custom components for high-performance vehicles.

Medical: Surgical instruments, implants, and other medical devices that require biocompatibility and precision.

Electronics: Housings, connectors, and other components requiring tight tolerances and smooth finishes.

Industrial Equipment: Custom machinery parts, tooling, and components for heavy equipment.

By offering comprehensive CNC machining services, Macraft can support a wide range of industries in producing high-precision, custom components that meet demanding application requirements.

About Us

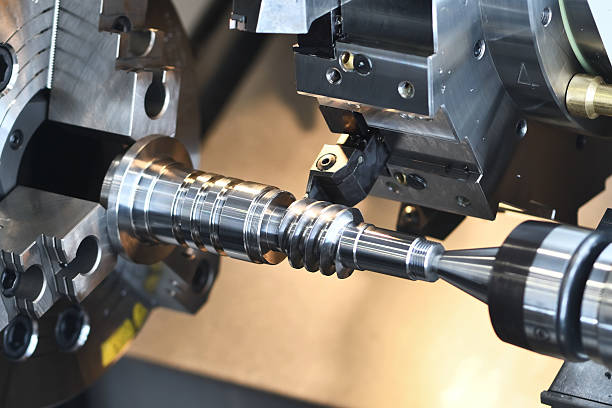

Turning

Macraft offers turning services, they provide a method for producing high-precision components with smooth finishes and tight tolerances. Here’s an overview of what Macraft’s turning services might include

Macraft’s Capabilities:

Material Expertise: Advising on the best materials for specific applications, ensuring optimal performance and durability.

Custom Turning: Offering the ability to produce custom parts tailored to specific designs, sizes, and performance requirements.

Prototyping: Providing turning services for prototype parts to validate designs before full-scale production.

High-Volume Production: Efficiently handling large production runs while maintaining consistent quality and short lead times.

Secondary Process:

Logistics: Managing the logistics of delivering turned parts to customers, ensuring timely and safe delivery.

Assembly: Assembling turned components into final products or sub-assemblies as required.

Surface Treatment: Providing coatings, anodizing, or other treatments to improve corrosion resistance, wear resistance, or other surface properties.

Packaging: Customized packaging solutions to protect the turned parts during transportation.

Industries we serve:

Consumer Goods: Custom components for products like furniture, appliances, and tools.

Automotive: Shafts, axles, and other cylindrical components requiring high precision and strength.

Aerospace: Precision components like bushings, bearings, and engine parts.

Industrial Equipment: Rollers, spindles, and other cylindrical parts for machinery and equipment.

Medical Devices: Surgical instruments, implants, and other precision components.

By offering comprehensive turning services, Macraft can support a wide range of industries in producing high-precision, custom components that meet demanding application requirements.

About Us

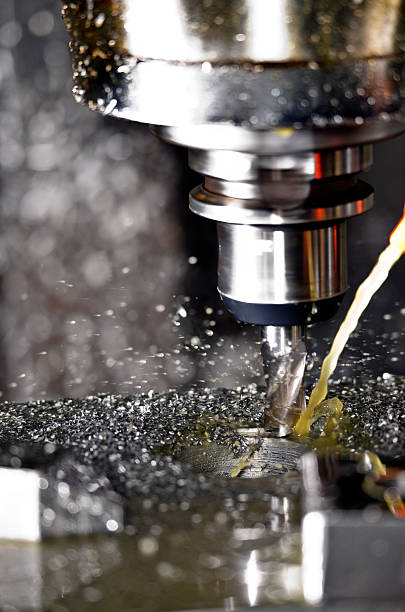

Milling

Macraft offers milling services, they provide a method for producing intricate and accurate components from various materials. Here’s an overview of what Macraft’s milling services might include:

Macraft’s Capabilities

Material Expertise: Advising on the best materials for specific applications, ensuring optimal performance and durability.:

Custom Milling: Offering the ability to produce custom parts tailored to specific designs, sizes, and performance requirements.

Prototyping: Providing milling services for prototype parts to validate designs before full-scale production.

High-Volume Production: Efficiently handling large production runs while maintaining consistent quality and short lead times.

Multi-Axis Milling: Equipped with advanced milling machines capable of 3-axis, 4-axis, and 5-axis machining, allowing for the creation of complex geometries.

Secondary Process:

Assembly: Assembling milled components into final products or sub-assemblies as required.

Surface Treatment: Providing coatings, anodizing, or other treatments to improve corrosion resistance, wear resistance, or other surface properties.

Packaging: Customized packaging solutions to protect the milled parts during transportation.

Logistics: Managing the logistics of delivering milled parts to customers, ensuring timely and safe delivery.

Industries we serve:

Consumer Goods: High-end custom products, accessories, and prototypes for consumer goods.

Aerospace: Structural components, engine parts, and other precision parts requiring high strength and accuracy.

Automotive: Engine blocks, transmission components, and custom parts for high-performance vehicles.

Medical Devices: Surgical instruments, implants, and other precision components.

Industrial Equipment: Custom machinery parts, tooling, and components for heavy equipment.

By offering comprehensive milling services, Macraft can support a wide range of industries in producing high-precision, custom components that meet demanding application requirements.

About Us

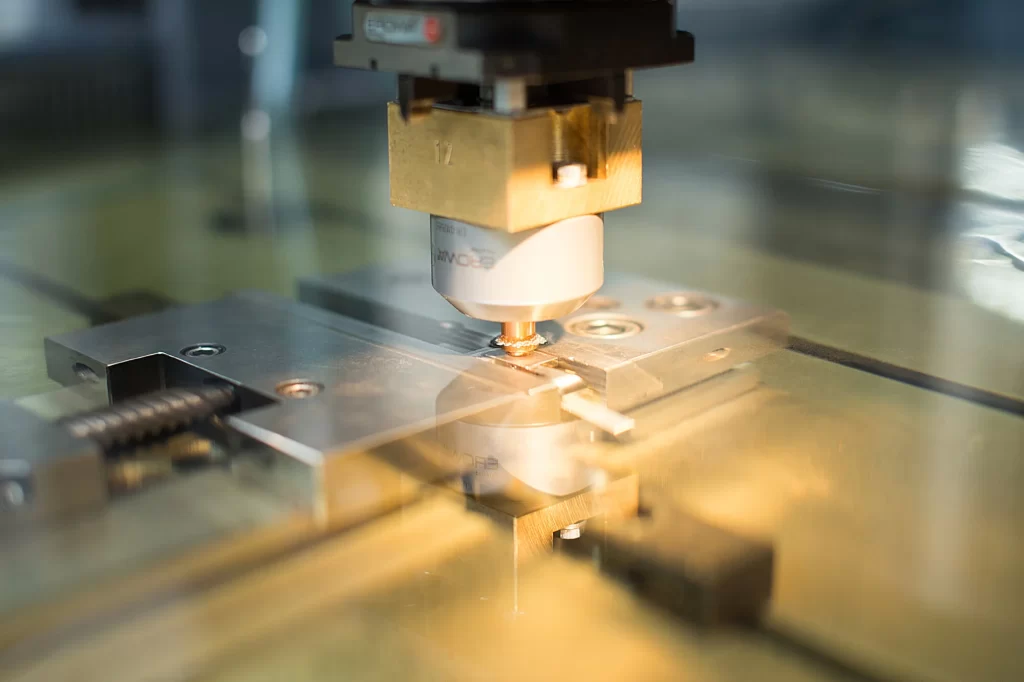

Electrical Discharge Machining (EDM)

Macraft offers EDM services, they provide a method for producing complex shapes and intricate details in hard materials. Here’s an overview of what Macraft’s EDM services might include:

Macraft’s Capabilities

Material Expertise: Advising on the best materials for specific applications, ensuring optimal performance and durability.

Custom EDM: Offering the ability to produce custom parts tailored to specific designs, sizes, and performance requirements.

Prototyping: Providing EDM services for prototype parts to validate designs before full-scale production.

High-Volume Production: Efficiently handling large production runs while maintaining consistent quality and short lead times.

Advanced EDM Technology: Equipped with state-of-the-art EDM machines capable of handling complex and intricate designs.

Secondary Process:

Logistics: Managing the logistics of delivering EDM parts to customers, ensuring timely and safe delivery.

Assembly: Assembling EDM components into final products or sub-assemblies as required.

Surface Treatment: Providing coatings, anodizing, or other treatments to improve corrosion resistance, wear resistance, or other surface properties.

Packaging: Customized packaging solutions to protect the EDM parts during transportation.

Industries we serve:

Tooling and Dies: Creating high-precision tooling, dies, and electrodes for various manufacturing processes.

Mold Making: Creating intricate cavities and features in molds used for plastic injection molding, die casting, and other processes.

Aerospace: Machining components for jet engines, turbine blades, and other high-strength parts.

Medical Devices: Producing precise components for surgical instruments, implants, and other medical devices.

Automotive: Manufacturing precision parts like fuel injectors, gears, and engine components.

By offering comprehensive EDM services, Macraft can support a wide range of industries in producing high-precision, custom components that meet demanding application requirements.