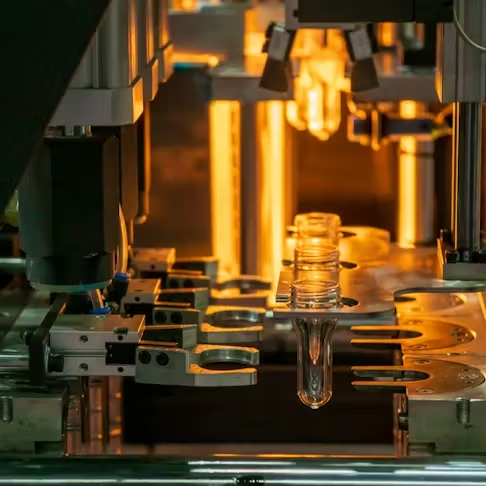

Injection Molding

Macraft offers injection molding services, providing solutions for manufacturing plastic parts and components. Injection molding is a widely used manufacturing process for producing large volumes of plastic parts with high precision and repeatability. Here’s an overview of what Macraft’s injection molding services might entail:

Macraft’s Capabilities

Custom Mold Design: Tailoring molds to meet specific customer requirements.

Prototyping: Creating prototypes to test and refine designs before full-scale production.

High-Volume Production: Efficiently handling large production runs with consistent quality.

Material Expertise: Advising on the best material choices for specific applications.

Quality Control: Implementing rigorous quality control measures to ensure all parts meet industry standards and customer specifications.

Additional Services:

Logistics: Managing the logistics of delivering parts to customers efficiently.

Assembly: Offering assembly services for multi-component products.

Packaging: Providing customized packaging solutions for finished parts.

Industries we serve :

Industrial: Various custom parts for machinery and equipment

Automotive: Components like dashboards, bumpers, and interior panels.

Consumer Goods: Products such as toys, household items, and packaging.

Electronics: Housings for devices, connectors, and other small parts.

Medical Devices: Disposable syringes, diagnostic equipment components, and more.

By offering comprehensive injection molding services, Macraft can support a wide range of industries and applications, ensuring high-quality, cost-effective manufacturing solutions for plastic parts and components.

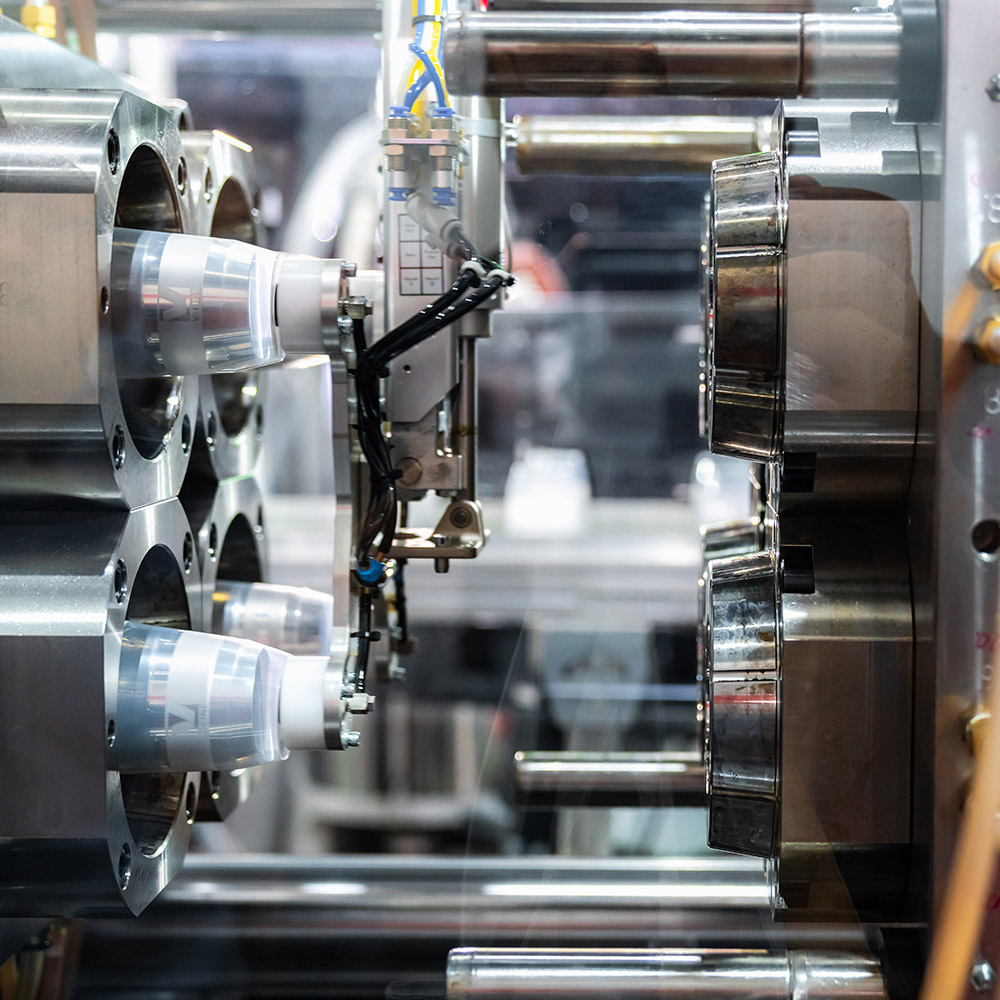

Blow Molding

Macraft offers blow molding services, will provide a range of solutions for producing high-quality, hollow plastic products. Here’s an overview of what Macraft’s blow molding services might entail:

Extrusion Blow Molding (EBM)

Injection Blow Molding (IBM)

Injection Stretch Blow Molding (ISBM)

Reheat and Blow Molding

Macraft’s Capabilities

Custom Mold Design: Designing molds to meet specific customer requirements.

Material Expertise: Advising on the best material choices for specific applications.

High-Volume Production: Efficiently handling large production runs with consistent quality.

Quality Control: Implementing rigorous quality control measures to ensure all parts meet industry standards and customer specifications.

Prototyping: Creating prototypes to test and refine designs before full-scale production

Additional Services

Logistics: Managing the logistics of delivering parts to customers efficiently.

Assembly: Offering assembly services for multi-component products.

Packaging: Providing customized packaging solutions for finished parts.

Industries we serve:

Consumer Goods: Toys, sporting goods, and other hollow consumer products.

Packaging: Bottles for beverages, personal care products, and household chemicals.

Automotive: Fuel tanks, ducting, and other hollow components.

Medical: Containers, bottles, and other hollow medical devices.

Industrial: Large containers, tanks, and custom hollow parts.

By offering comprehensive blow molding services, Macraft can support a wide range of industries and applications, ensuring high-quality, cost-effective manufacturing solutions for hollow plastic parts and containers.

Plastic Extrusion

Macraft offers plastic extrusion services, will provide the solutions for creating various plastic products with consistent cross-sectional shapes. Here’s an overview of what Macraft’s plastic extrusion services might entail:

Profile Extrusion

Sheet Extrusion

Blown Film Extrusion

Tubing Extrusion

Coextrusion

Macraft’s Capabilities

Prototyping: Creating prototypes to test and refine designs before full-scale production.

Custom Die Design: Designing dies to produce specific profiles and shapes according to customer requirements.

Material Expertise: Advising on the best material choices for specific applications.

High-Volume Production: Efficiently handling large production runs with consistent quality.

Quality Control: Implementing rigorous quality control measures to ensure all extruded products meet industry standards and customer specifications.

Additional Services

Logistics: Managing the logistics of delivering products to customers efficiently.

Assembly: Offering assembly services for multi-component products.

Packaging: Providing customized packaging solutions for finished products.

Industries we serve:

Industrial: Custom profiles for machinery and equipment.

Construction: Pipes, siding, window frames, and insulation materials.

Automotive: Trim, seals, and tubing.

Packaging: Films, sheets, and flexible packaging materials.

Consumer Goods: Profiles for furniture, toys, and household items.

Medical: Tubing and components for medical devices.

By offering comprehensive plastic extrusion services, Macraft can support a wide range of industries and applications, ensuring high-quality, cost-effective manufacturing solutions for various plastic products.

Thermoforming

Macraft offers thermoforming services, will provide the solutions for producing a variety of plastic products with detailed shapes and textures. Here’s an overview of what Macraft’s thermoforming services might entail:.

Thin-Gauge Thermoforming

Thick-Gauge Thermoforming

Macraft’s Capabilities

Custom Mold Design: Designing and fabricating molds to meet specific customer requirements.

Material Expertise: Advising on the best material choices for specific applications.

Prototyping: Creating prototypes to test and refine designs before full-scale production.

High-Volume Production: Efficiently handling large production runs with consistent quality.

Quality Control: Implementing rigorous quality control measures to ensure all products meet industry standards and customer specifications.

Additional Services

Assembly: Offering assembly services for multi-component products.

Packaging: Providing customized packaging solutions for finished products.

Logistics: Managing the logistics of delivering products to customers efficiently

Industries We Serve:

Industrial: Equipment enclosures, pallets, and custom trays

Packaging: Custom trays, clamshells, blister packs, and other protective packaging solutions.

Automotive: Interior panels, dashboards, and other custom components.

Medical: Disposable medical trays, equipment housings, and protective covers.

Consumer Products: Housings for electronic devices, appliance components, and other consumer goods.

By offering comprehensive thermoforming services, Macraft can support a wide range of industries and applications, ensuring high-quality, cost-effective manufacturing solutions for various plastic products.

Roto Molding

Macraft offers rotational molding (roto molding) services, providing solutions for producing durable and complex hollow plastic products. Here’s an overview of what Macraft’s rotational molding services might entail:

Macraft’s Capabilities

Color and Finish Options: Offering a variety of colors and surface finishes to meet aesthetic and functional needs.

Custom Mold Design: Designing molds to meet specific customer requirements, including complex geometries and detailed features.

Material Expertise: Advising on the best material choices for specific applications to ensure optimal performance and durability.

Prototyping: Creating prototypes to test and refine designs before full-scale production.

High-Volume Production: Efficiently handling large production runs with consistent quality.

Additional Services

Logistics: Managing the logistics of delivering parts to customers efficiently.

Assembly: Offering assembly services for multi-component products.

Customization: Providing custom colors, textures, and finishes.

Packaging: Providing customized packaging solutions for finished parts.

Industries we serve

Consumer Goods: Toys, containers, and household items.

Storage Tanks: Chemical tanks, water storage tanks, and fuel tanks.

Automotive: Fuel tanks, air ducts, and interior components.

Outdoor and Recreational Products: Kayaks, playground equipment, and outdoor furniture.

Industrial Applications: Containers, bins, and custom industrial parts.

By offering comprehensive rotational molding services, Macraft can support a wide range of industries and applications, ensuring high-quality, cost-effective manufacturing solutions for various hollow plastic products.

Compression Molding

Macraft offers compression molding services, will provide the solutions for producing durable and precise parts from a variety of thermoset and thermoplastic materials. Here’s an overview of what Macraft’s compression molding services might entail:

Macraft’s Capabilities

Precision and Consistency: Ensuring high precision and consistency in every part produced.

Custom Mold Design: Designing molds to meet specific customer requirements, including complex geometries and detailed features.

Material Expertise: Advising on the best material choices for specific applications to ensure optimal performance and durability.

Prototyping: Creating prototypes to test and refine designs before full-scale production.

High-Volume Production: Efficiently handling large production runs with consistent quality.

Additional Services

Logistics: Managing the logistics of delivering parts to customers efficiently.

Assembly: Offering assembly services for multi-component products.

Customization: Providing custom colors, textures, and finishes.

Packaging: Providing customized packaging solutions for finished parts.

Industries we serve

Industrial: Gaskets, seals, and machinery parts.

Automotive: Components like brake pads, bumpers, and interior panels.

Aerospace: Structural components and interior parts.

Electrical: Insulators, switchgear, and other electrical components.

Consumer Goods: Kitchenware, appliance parts, and furniture components.

By offering comprehensive compression molding services, Macraft can support a wide range of industries and applications, ensuring high-quality, cost-effective manufacturing solutions for various composite and plastic parts.

Additive Manufacturing

Macraft offers additive manufacturing services, will provide the solutions for producing intricate and custom parts with a high degree of precision and flexibility. Here’s an overview of what Macraft’s additive manufacturing services might entail:

Fused Deposition Modeling (FDM)

Stereolithography (SLA)

Selective Laser Sintering (SLS)

Direct Metal Laser Sintering (DMLS)

Binder Jetting

Macraft’s Capabilities

Precision and Consistency: Ensuring high precision and consistency in every part produced

Design Assistance: Offering design services to optimize parts for additive manufacturing.

Material Expertise: Advising on the best material choices for specific applications to ensure optimal performance and durability.

Prototyping: Creating prototypes to test and refine designs before full-scale production.

High-Volume Production: Capable of scaling up production to meet high-volume demands.

Additional Services

Logistics: Managing the logistics of delivering parts to customers efficiently.

Assembly: Offering assembly services for multi-component products.

Customization: Providing custom colors, textures, and finishes.

Packaging: Providing customized packaging solutions for finished parts.

industries we serve:

Industrial: Functional parts, custom tools, and replacement components.

Prototyping: Creating prototypes for design validation, testing, and iteration.

Medical: Custom prosthetics, implants, and medical devices.

Aerospace: Lightweight components, complex geometries, and customized parts.

Automotive: Custom parts, tools, and fixtures.

Consumer Goods: Custom products, toys, and household items.

By offering comprehensive additive manufacturing services, Macraft can support a wide range of industries and applications, ensuring high-quality, cost-effective manufacturing solutions for complex and custom parts.

Vacuum Forming

Macraft offers vacuum forming services, will provide the solutions for creating detailed and durable plastic components with a high degree of efficiency and precision. Here’s an overview of what Macraft’s vacuum forming services might entail:

Macraft’s Capabilities

Precision and Consistency: Ensuring high precision and consistency in every part produced.

Custom Mold Design: Designing and fabricating molds to meet specific customer requirements, including complex shapes and detailed features.

Material Expertise: Advising on the best material choices for specific applications to ensure optimal performance and durability.

Prototyping: Creating prototypes to test and refine designs before full-scale production.

High-Volume Production: Efficiently handling large production runs with consistent quality.

Additional Services

Logistics: Managing the logistics of delivering parts to customers efficiently

Assembly: Offering assembly services for multi-component products.

Customization: Providing custom colors, textures, and finishes.

Packaging: Providing customized packaging solutions for finished parts.

Industries we serve:

Signage and Displays: Point-of-sale displays, signage, and advertising materials.

Packaging: Custom trays, blister packs, clamshells, and protective packaging.

Automotive: Interior panels, dashboards, and custom components.

Medical: Disposable medical trays, equipment housings, and protective covers.

Consumer Goods: Housings for electronic devices, appliance components, and other consumer goods.

Industrial: Equipment enclosures, pallets, and custom trays.

By offering comprehensive vacuum forming services, Macraft can support a wide range of industries and applications, ensuring high-quality, cost-effective manufacturing solutions for various plastic products.

Rubber and Silicone Molding

Macraft offers rubber and silicone molding services, will provide the solutions for producing precision parts with excellent mechanical properties and resistance to extreme conditions. Here’s an overview of what Macraft’s rubber and silicone molding services might entail:

Compression Molding

Injection Molding

Transfer Molding

Macraft’s Capabilities

Precision and Consistency: Ensuring high precision and consistency in every part produced.

Custom Mold Design: Designing molds to meet specific customer requirements, including complex geometries and detailed features.

Material Expertise: Advising on the best rubber or silicone materials for specific applications to ensure optimal performance and durability.

Prototyping: Creating prototypes to test and refine designs before full-scale production.

High-Volume Production: Efficiently handling large production runs with consistent quality.

Additional Services

Logistics: Managing the logistics of delivering parts to customers efficiently

Assembly: Offering assembly services for multi-component products.

Customization: Providing custom colors, textures, and finishes.

Packaging: Providing customized packaging solutions for finished parts.

Industries we serve:

Industrial: Seals, gaskets, hoses, and custom parts for machinery

Automotive: Seals, gaskets, hoses, and vibration dampening components.

Medical: Medical devices, seals, gaskets, and tubing.

Electronics: Keypads, seals, connectors, and insulators.

Consumer Goods: Kitchenware, seals, and household items.

Aerospace: Seals, gaskets, and vibration dampening components.

By offering comprehensive rubber and silicone molding services, Macraft can support a wide range of industries and applications, ensuring high-quality, cost-effective manufacturing solutions for various flexible and durable parts.

Metal Injection Molding

Macraft offers Metal Injection Molding (MIM) services, they provide a method for producing complex metal parts with high precision and fine details. Here’s an overview of what Macraft’s MIM services might include:

Macraft’s Capabilities:

Material Expertise: Advising on the best metal powders and binder systems for specific applications, ensuring optimal performance and durability..

Custom MIM: Offering the ability to produce custom metal parts tailored to specific designs, sizes, and performance requirements.

Prototyping: Providing MIM services for prototype parts to validate designs before full-scale production.

High-Volume Production: Efficiently handling large production runs while maintaining consistent quality and short lead times.

Additional Services

Logistics: Managing the logistics of delivering MIM parts to customers, ensuring timely and safe delivery.

Surface Treatment: Providing coatings, anodizing, or other treatments to improve corrosion resistance, wear resistance, or other surface properties.

Packaging: Customized packaging solutions to protect the MIM parts during transportation.

Industries we serve:

Industrial Equipment: Custom components for machinery, tools, and other industrial applications.

Aerospace: Precision components for aircraft engines, avionics, and structural applications.

Automotive: Small, complex parts such as gears, fasteners, and components for fuel systems and transmissions.

Medical Devices: Surgical instruments, implants, and components for medical equipment.

Consumer Electronics: High-precision metal parts for smartphones, tablets, and other electronic devices.

By offering comprehensive Metal Injection Molding (MIM) services, Macraft can support a wide range of industries in producing high-precision, complex metal components that meet demanding application requirements.